Capabilities

Single Layer Extrusion

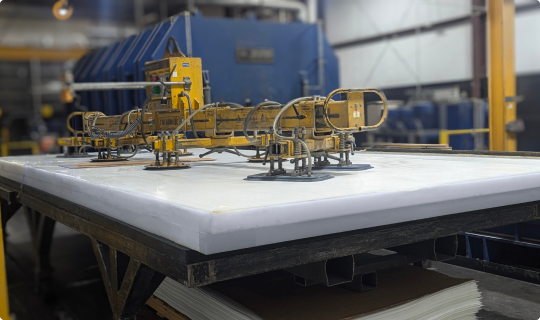

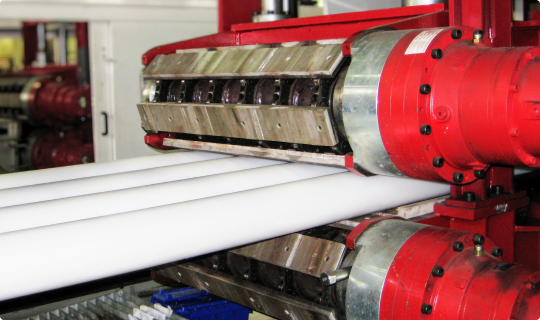

Polymer Industries utilizes a single screw continuous sheet extrusion process in which plastic pellets are fed into the barrel of the extruder and conveyed by a screw out the other end of the extruder.

The heaters outside of the barrel as well as the friction from the rotation of the screw melt the plastic pellets into a sheet form, which is then placed on a 3 roll stack.

These rolls are water cooled and help to take the heat out of the plastic. After the plastic comes off the top roll, it travels down the conveyor where numerous operations help to stress relieve the sheet as well as apply the desired surface finish. Once the plastic reaches the end of the sheet line, a saw cuts the sheet to size.

Co-Extrusion

Polymer Industries also utilizes a co-extrusion process in which two extruders feed the die to form a continuous sheet.

The main extruder feeds the middle “B” layer of the sheet while the co-extruder feeds the outside “A” layers.

This process is used where different colors or formulations of materials are required on the skin surface versus the middle of the sheet. This process is used to manufacture our Densetec® Sign Board and Densetec® AntiSkid materials.

Surface Finishes

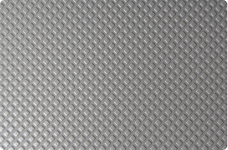

Anti Skid Diamond

Anti Skid Dot

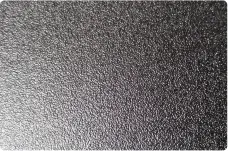

Cobble Stone

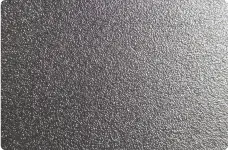

Desert Sand

Orange Peel

Smooth

Wood Grain

Polymer Industries utilizes compression molding to produce Polypropylene, High Molecular Weight Polyethylene, Low Density Polyethylene, and High Density Polyethylene sheets at thicknesses of 1 1/2″ and above and all Ultra-High Molecular Weight sheet products.

Since Ultra-High Molecular Weight is a material that does not flow when it melts, it has to be ram extruded or compression molded.

Compression molding involves placing material in a metal mold shaped as a sheet, which is then heated and pressed to form the sheet. After molding, the sheet’s edges are trimmed for a quality finish. Sheets can be sold as-is with a 10% thickness tolerance or planed to the desired thickness.

Lengths Molded

Up to 20′. Standard lengths are 96″ and 120″ on Densetec® Materials.

Standard length is 120″ on Polyslick® Ultra-High Molecular Weight.

Widths Molded

Up to 8′. Standard width is 4′.

Polymer Industries uses a ram extrusion process for the manufacture of its Polyslick® Ultra-High Molecular Weight rod, tubing, and profiles. First, Ultra-High Molecular Weight powder is gravity fed into a chamber and a hydraulic ram pushes the powder from this chamber into the die (the shape of the desired plastic, a certain diameter rod, a certain OD and ID tube, or a profile shape).

Heaters are then employed on the outside of the die to heat the plastic and make it form into shape. The hydraulic ram moves back and forth continuously feeding the powder into the die. As the material comes out of the die, it travels the length of the conveyor after which it is cut to length.

Ram extrusion does not shear the material that is being manufactured; it moves the material by hydraulically pushing it through the die. Ultra-High Molecular Weight Polyethylene, which becomes gelatinous when it melts, can only be extruded with this process or similar.

Lengths Extruded

Standard lengths are 120″. We can also cut our ram extruded products to other lengths upon request.

For example, if a customer desires 10″ rod cut into 6″ long pieces, this can be done with a cold saw that cuts large diameter rods to length.

Diameters Extruded

Up to 10″.

Polymer Industries uses a comprehensive range of fabrication equipment to meet our customers’ needs. We can supply products at any stage, from cut-to-size blanks to fully finished parts. Our 3-axis CNC routers can create nearly any part required, and for tasks beyond their capabilities, we use our CNC mills and lathes.

We also have several advanced CNC panel saws for precise cut-to-size pieces, which many customers prefer to minimize handling on their end. We are able to plane sheets to within .005″ on our planer which will plane full sheets up to 54″ wide. Additionally, our horizontal band saws can cut large diameter rods to any desired size. All products are fabricated at our manufacturing facilities.

Equipment

CNC Routers

CNC Panel Saws

CNC Mills

CNC Lathes

Table Saws

Planer

Horizontal Band Saws

Annealing

Centerless Grinding

Mechanical Extrusion

Skiving