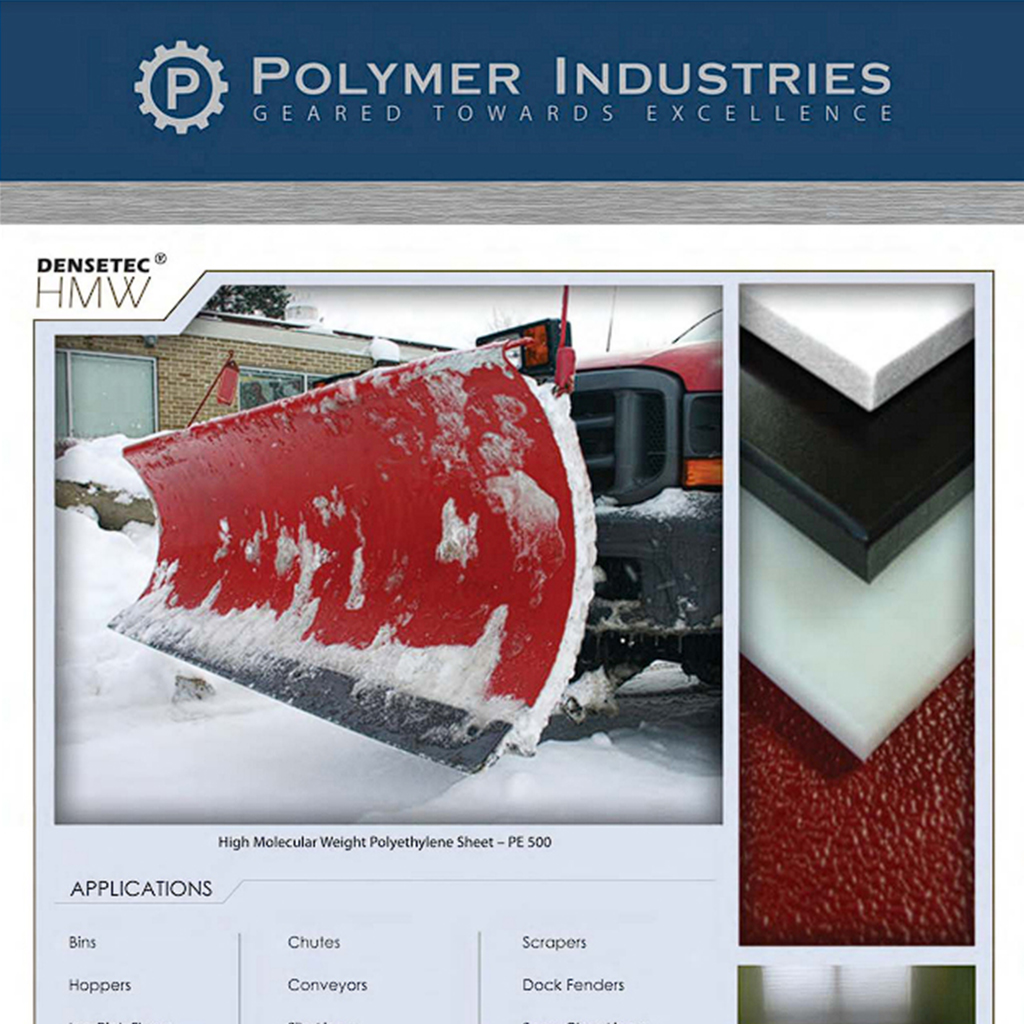

DENSETEC HMW

Polymer Industries’ Densetec® HMW is the extruded material needed when Densetec® HDPE is not enough and Polyslick® UHMW is not necessary. Densetec® HMW has higher impact strength than HDPE and is more abrasion resistant. The fact that Densetec® HMW is more wear resistant than standard HDPE, and is more economical than standard UHMW makes it the ideal material for wear applications and machined parts. It may also be used in applications such as snowplow linings and fertilizer spreaders.

Have questions or need samples?

Features

- Noise reduction

- Low temp properties

- Good sliding qualities

- Stress crack resistant

- RoHS & REACH compliant

- Moisture resistant

- Low coef of friction

- High impact strength

- Excellent wear resistance

- Excellent chemical resistance

Colors

White

Black

* Natural

*FDA approved colors

Finishes

Smooth

*Note: Other sizes, colors, formulations and forming grade available upon request

Applications

- Bins

- Hoppers

- Ice Rink Floors

- Reclaim Hoppers

- Wear Applications

- Chutes

- Conveyors

- Silo Liners

- Truck Liners

- Vibratory Feed Pans

- Scrapers

- Dock Fenders

- Snow Plow Liners

- Fertilizer Spreaders

- Various Machine Parts

Sizes

Capabilities

Extruded

Thickness

0.03 – 1.25 inch / 0.8 – 32 mm

Width

45 – 144 inch / 1140 – 3655 mm

Length

Up to 480 inch / 12200 mm

Compression Molded

Thickness

0.5 – 4 inch / 12.7 – 100 mm

Width

48 – 96 inch / 1220 – 2440 mm

Length

Up to 240 inch / 6100 mm

Standard

Extruded

Thickness

0.03 – 1 inch / 0.8 – 25 mm

Sheet Size

48 x 96 inch / 1220 x 2440 mm

48 x 120 inch / 1220 x 3050 mm