Our Industries

Plastics are used in numerous industrial applications to improve safety, reduce cost and weight, increase color options while not requiring paint, and be corrosion resistant.

The use of plastics in the aerospace industry continues to increase each year to make components lighter, more chemical resistant, and more economical than metals that were more heavily utilized in the past.

Plastics used in the agriculture industry help to strengthen parts, allow components to last longer, improve overall harvesting speed, and eliminate repair and replacement cost across many applications.

Performance plastics play an important role in the production of solar, wind, wave, biofuels, geothermal and hydrogen equipment components.

More durable, lightweight, fuel efficient designs in today’s cars all benefit from innovations made in the plastic industry. The variety of applications grows each year along with other innovations to build the cars of the future.

In the building and construction industry, plastics are used as a direct replacement for wood and metal in many applications. Some plastics are even strong enough to protect homes and businesses against hurricane force winds.

Strong chemicals can easily weaken and destroy many metals and other materials. In chemical processing plants, plastics are used to help build systems strong enough to handle harsh chemicals in extreme environments and conditions.

There’s a plastic to meet every standard and use for electrical applications. The next time you need a stable, impact-resistant, easy-to-process, safe material- think performance plastics.

Not only do performance plastics have a low overall lifecycle carbon footprint, including being recyclable,

they are used directly in applications that help preserve and restore the world in which we live.

Plastic materials are used in large food processing and bottling conveyor systems to keep things running smooth. Machinery applications including friction and wear parts, valves to handle fluids, and plastic sheet materials for easy-to-clean cutting boards.

How do you ensure that your lab, semiconductor, or food processing applications won’t be contaminated by materials in transport? It’s easy… use performance plastics!

Cranes, bulldozers, dump trucks, and other machinery and vehicles all get assistance from plastic. Horsepower and a variety of plastics work together to accomplish large jobs without damaging the valuable equipment or slowing down the project.

Life sciences applications demand durability, reliability, regulatory compliance, traceability from raw

materials and design flexibility. What’s the Rx for life sciences’ needs? Performance plastics, of course!

Lumber and paper processing operations that use performance plastics instead of metal parts have longer wearing, are less noisy, and use more reliable equipment that performs better. Clearly, plastics are a cut above the rest!

In the Marine Industry plastics are a popular choice for large applications because they are resistant to saltwater, UV, chemicals, and corrosion. Flexible materials are used to help protect passengers, docks, and other structures year after year.

Specialized equipment gets help from a wide array of plastics to quickly move items of all sizes from one place to another. Plastics play a key role in helping protect the materials and the equipment so both can keep moving along smoothly.

Plastics are heavily used in the medical industry because of their unique properties and capabilities. Unlike some materials, plastics are extremely resistant to most chemicals, easy to sterilize, and are both strong and lightweight.

Getting valuable resources from underground to create energy and other products is not an easy job. The plastics used in mining applications are designed to be long lasting and are required to perform in very demanding environments.

Performance plastics provide numerous advantages for any maintenance, repairs and operations manufacturing operation. They’re lightweight, hold up well under extreme conditions, and are an excellent cost-effective alternative to metal.

The oil & gas industry offers challenging applications in extreme regions and plastics play a key role. These harsh conditions demand high performance plastics with a wide temperature range, chemical resistance, toughness, flexibility, and long-term reliability.

Performance plastics are booming in the pharmaceutical industry because of their durability, ability to be

sterilized, easy machinability to exacting specifications, and cost effectiveness.

Lumber and paper processing operations often choose plastics over metal parts because they weigh less, are chemically resistant, create less product damage, wear longer, and help drive long term efficiency.

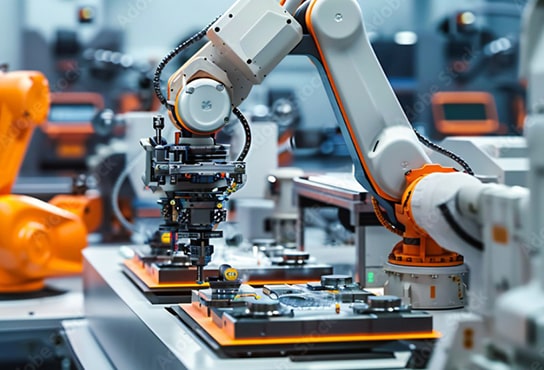

Semiconductor manufacturing involves harsh chemicals, exacting high purity requirements and resistance

to electrical shock, as well as cost effectiveness.

Plastic signs outperform wood and metal signs because of their design flexibility and weight. The range of colors and options can be seen in quiet golf courses and parks or in busy downtown business areas and entertainment complexes.

The sports and recreation industry includes a wide variety of applications in playgrounds, pools, parks, ice skating rinks, and many other indoor and outdoor places where you can find plastics in use today.

The transportation industry relies on a variety of plastics to help get things safely from one place to another. Applications include anti-slip surfaces, baggage handling systems, truck liners, snow plows, dock pads, and bus stations to name a few.

Plastics are used throughout the world to build durable, long-lasting, maintenance-free water transport systems. Wastewater treatment facilities also include plastic components in tanks, pumps, bearings, impellers and valve parts that require chemical resistance and durability.