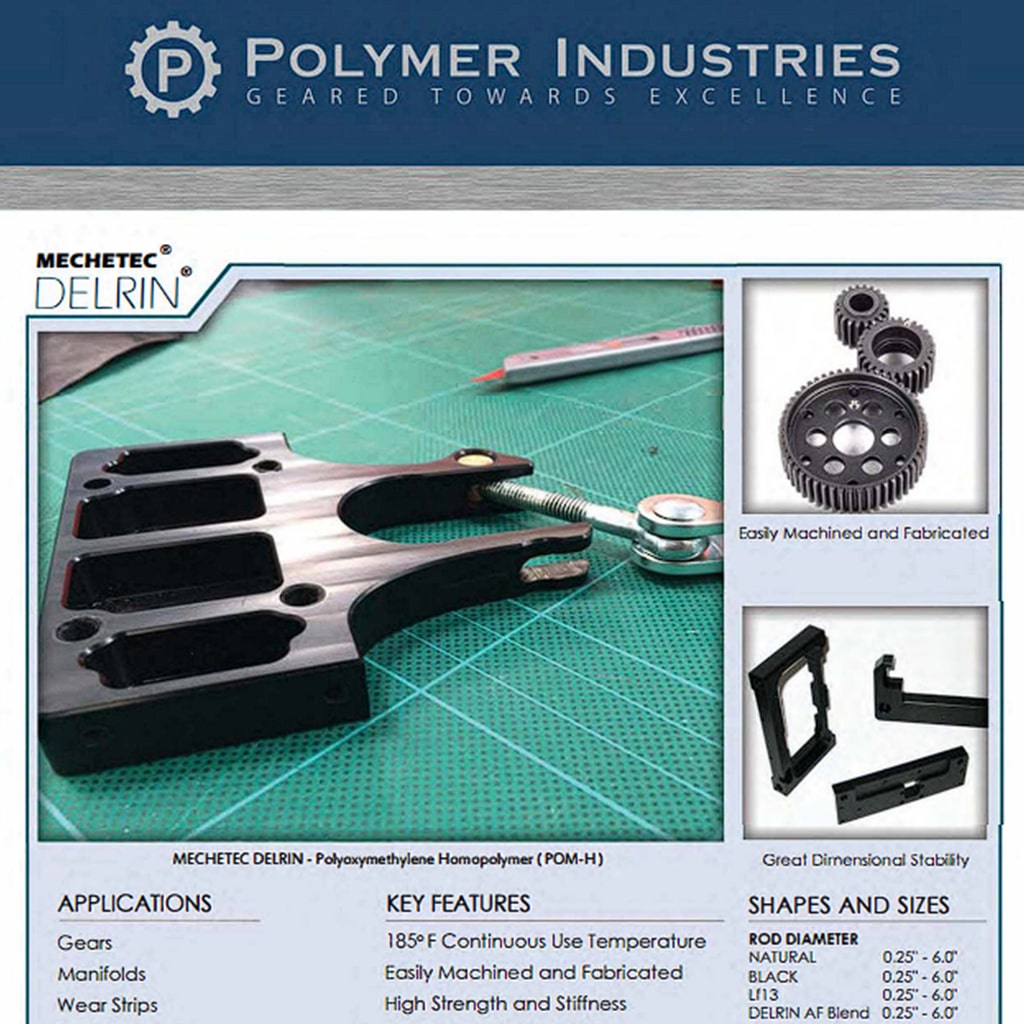

MECHETEC DELRIN

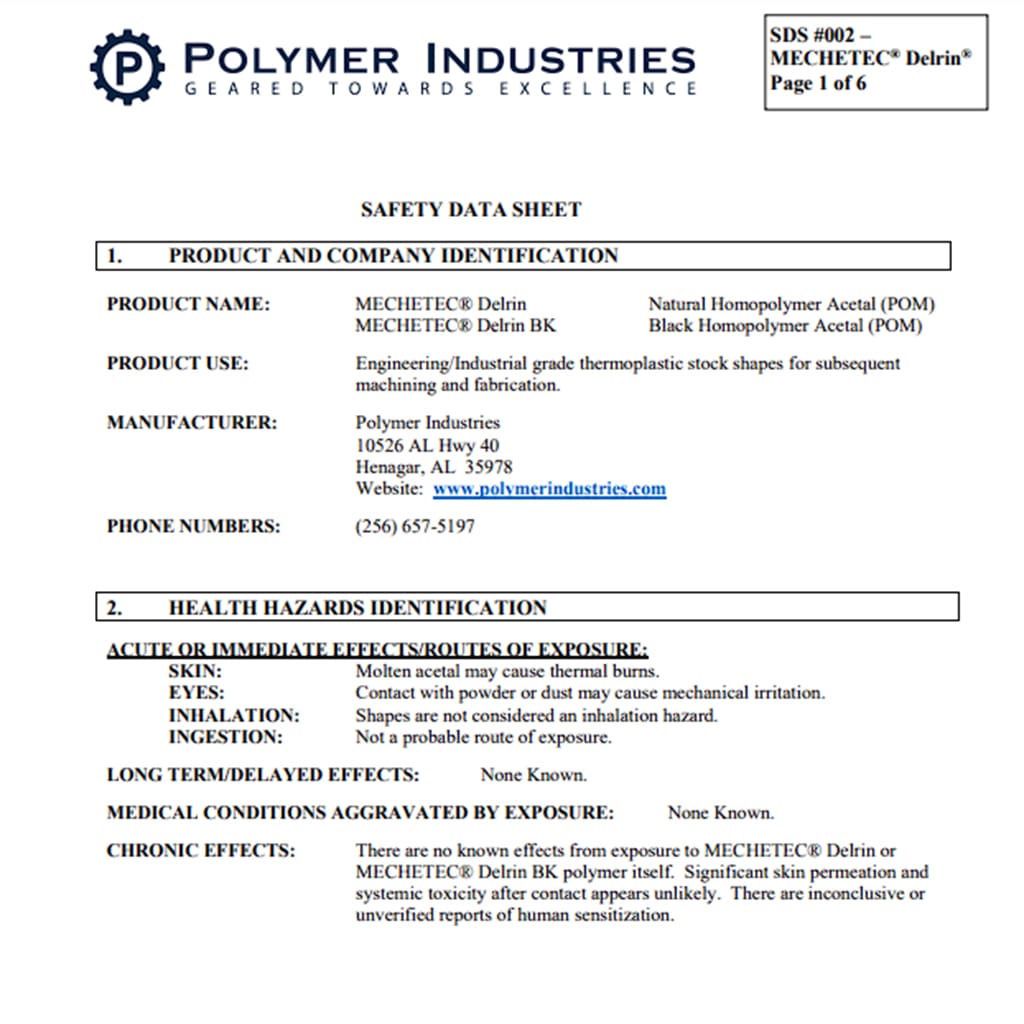

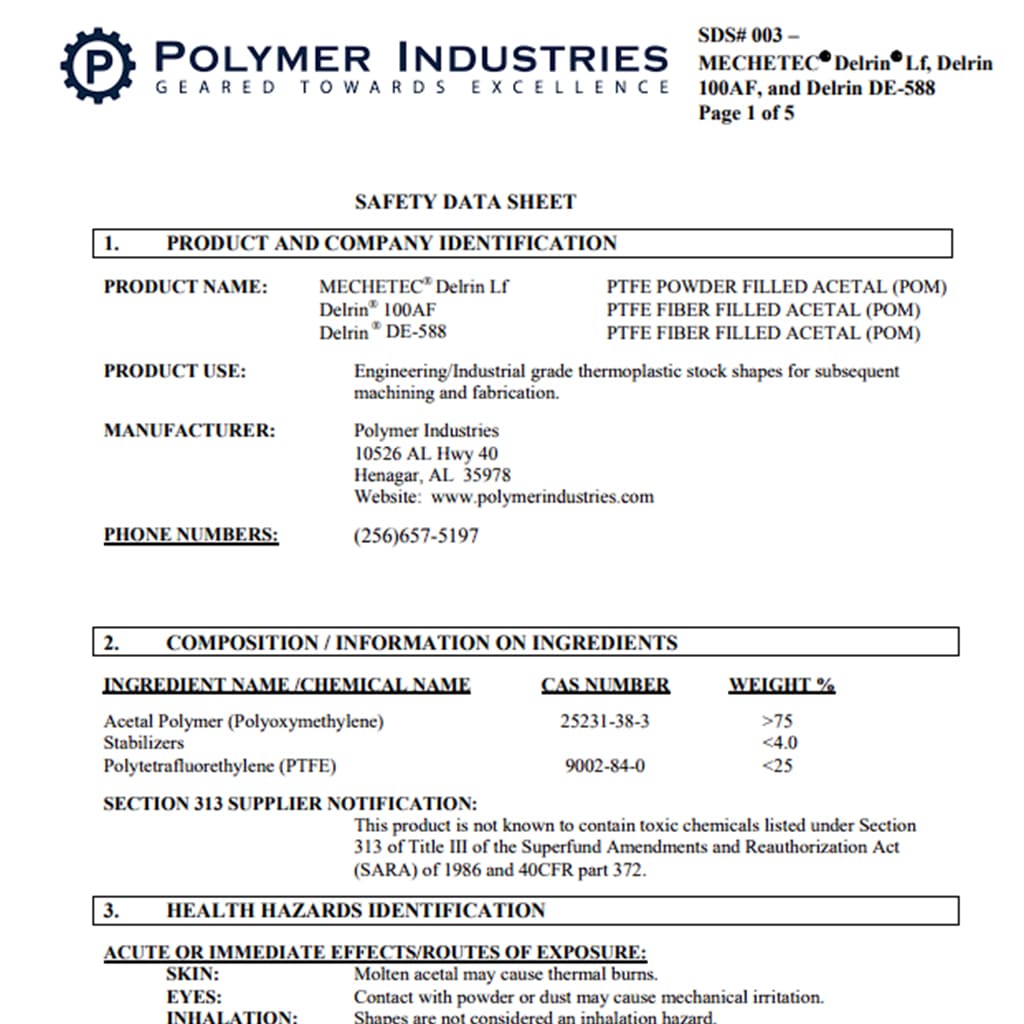

MECHETEC® Delrin® (polyoxy-methylene) offers design engineers a superior blend of strength, stiffness, lubricity, and dimensional stability. These properties, along with inherent machining ease, have made MECHETEC® Delrin® one of the most widely used engineering grade thermoplastics. To meet specific application configurations and to maximize production efficiencies, Polymer Industries offers a broad array of MECHETEC® Delrin® stock shapes. These materials include both homopolymer unfilled grades as well as PTFE-filled grades for enhanced wear resistance and DE-588 options for military applications.

Formally known as Unital Delrin. For more Info :

Have questions or need samples?

Features

- 185° F Continuous Use Temperature

- Easily Machined and Fabricated

- High Strength and Stiffness

- Superior Wear Resistance

- Excellent Toughness

Colors

Natural

Black

Teflon-Filled

Applications

- Gears

- Manifolds

- Wear Strips

- Timing Screws

- Pump Components

- Bushings and Bearings

Formulations

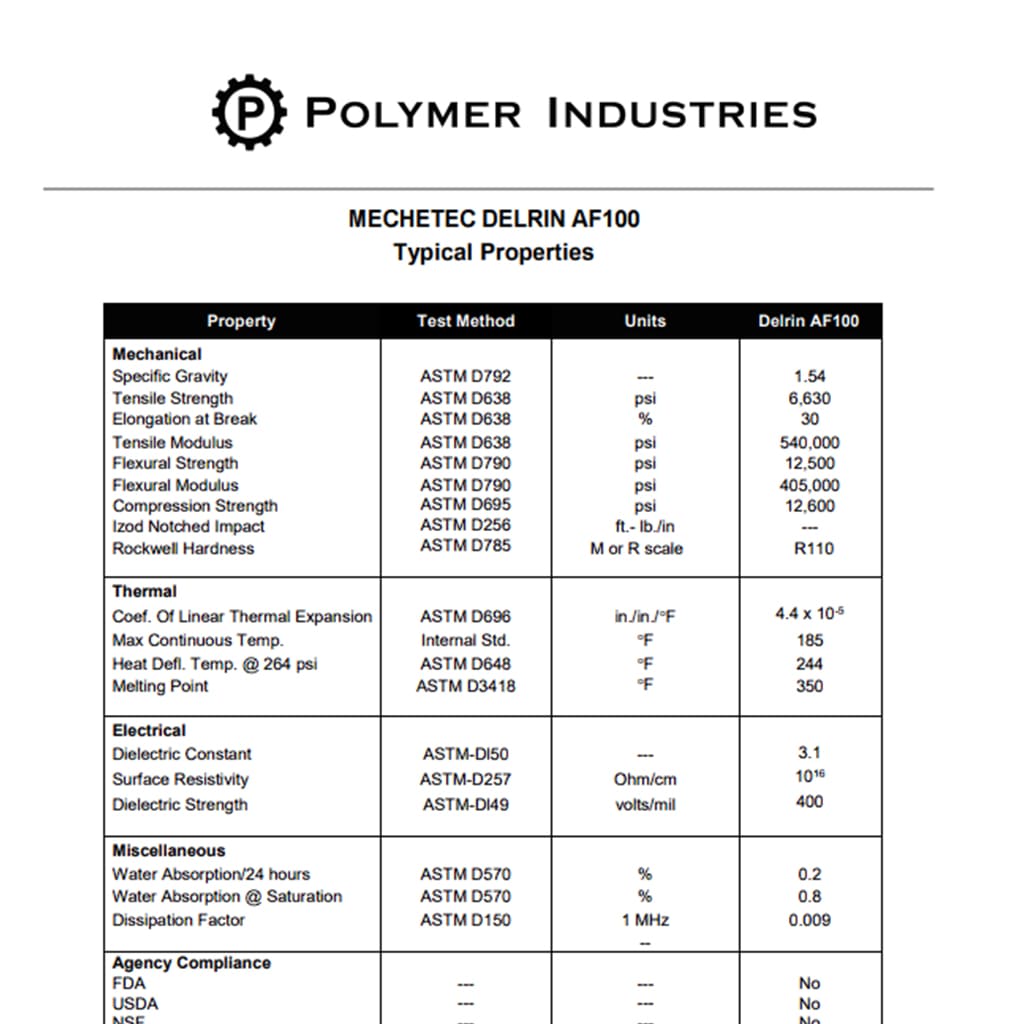

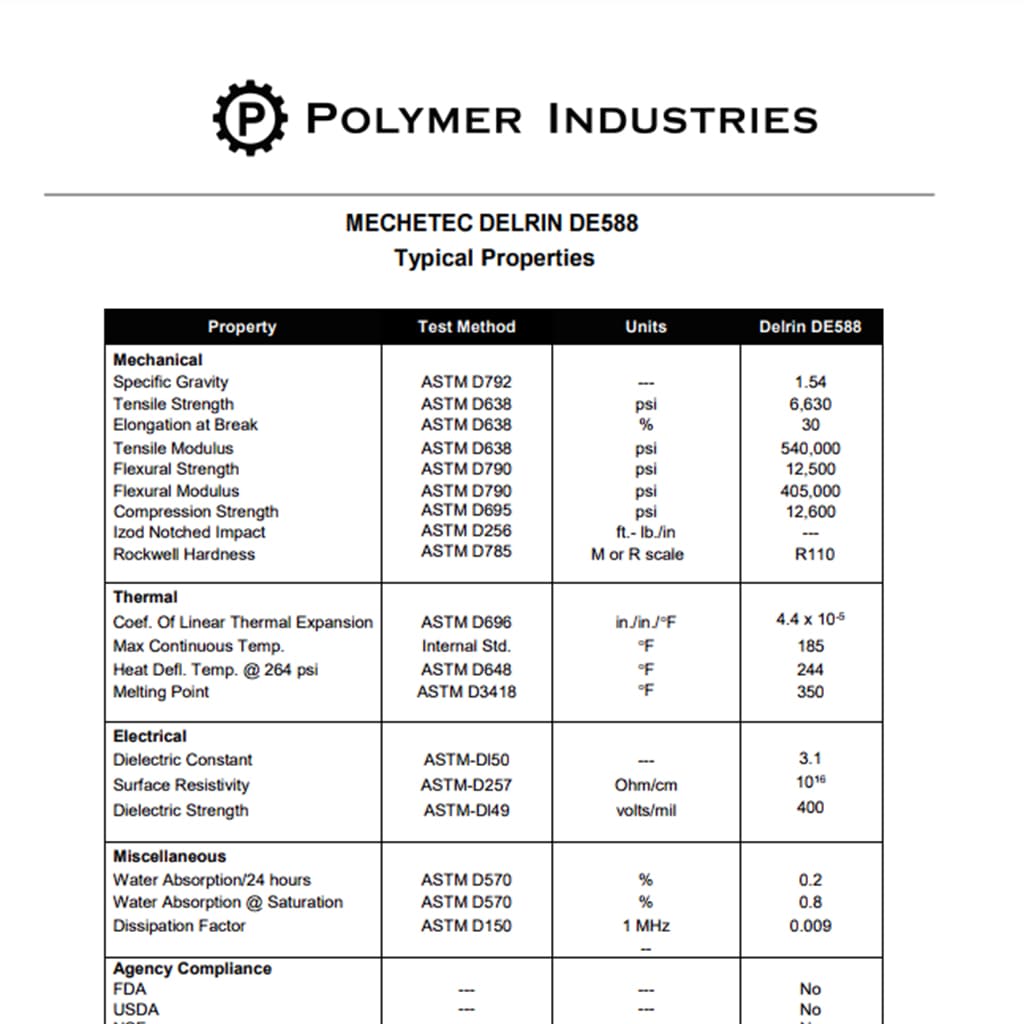

- Teflon filled:

- 20% fiber (100AF)

- 13% fiber (AF Blend)

- 13% powder (LF13)

- 20% fiber (DE588)

Sizes

Unfilled

Extruded Sheet

Thickness

0.25 – 3.00 inch / 6 – 76 mm

Sheet Size

24 x 48 inch / 610 x 1220 mm

Extruded Rod

Diameter

0.25 – 6.00 inch / 6 – 152 mm

Length

96 inch / 2438 mm

PTFE-Filled

Extruded Sheet

Thickness

0.25 – 3.00 inch / 6 – 76 mm

Sheet Size

24 x 48 inch / 610 x 1220 mm

Extruded Rod

Diameter

0.25 – 8.00 inch / 6 – 203 mm

Length

96 inch / 2438 mm