POLYSLICK PILE GUARDS

The docking or berthing of a ship puts an enormous pressure and friction transferred between the ship and the shore fixtures. This can lead to large scale damage and deterioration to the shore fixtures. Traditionally, docks have used rubber and timber systems to provide a barrier between the ship and the dock. However, timber quickly deteriorates in the harsh marine climate while rubber is prone to tearing and catastrophic failure in this application.

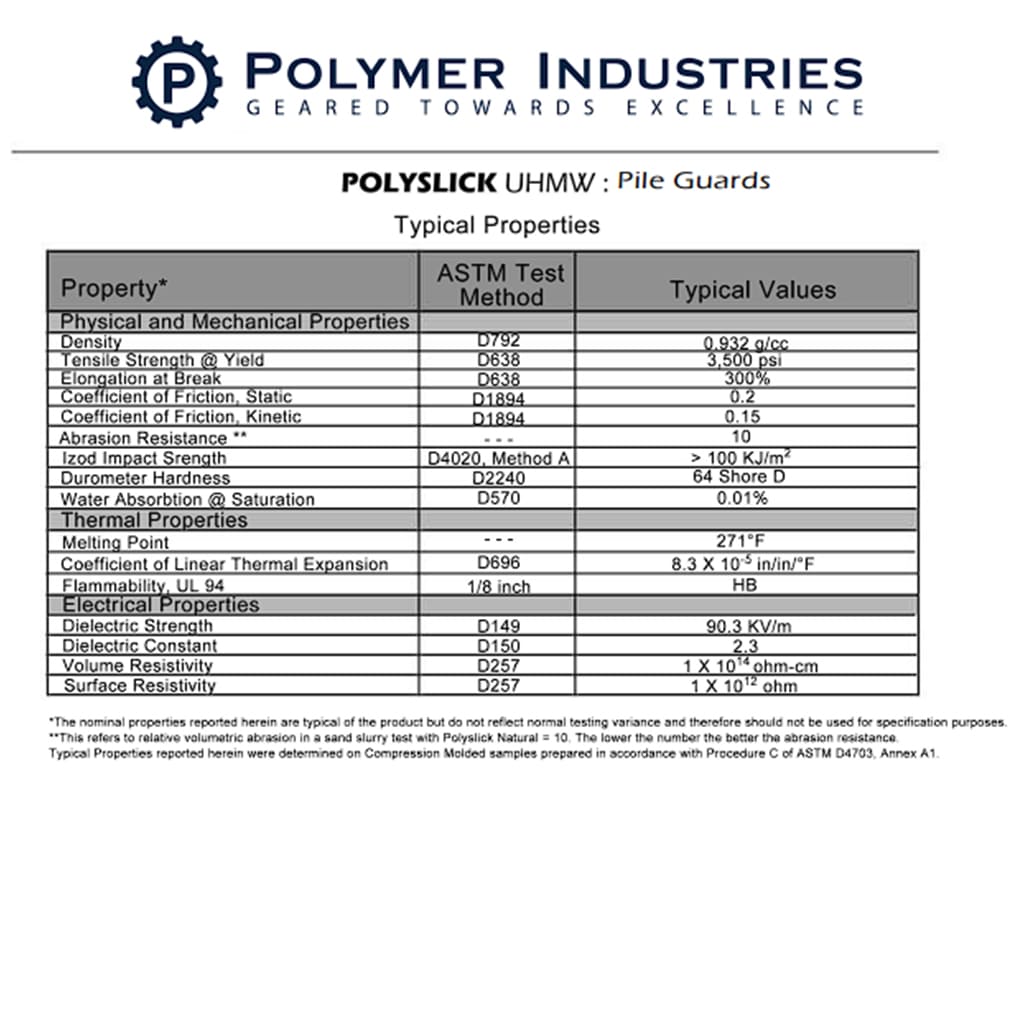

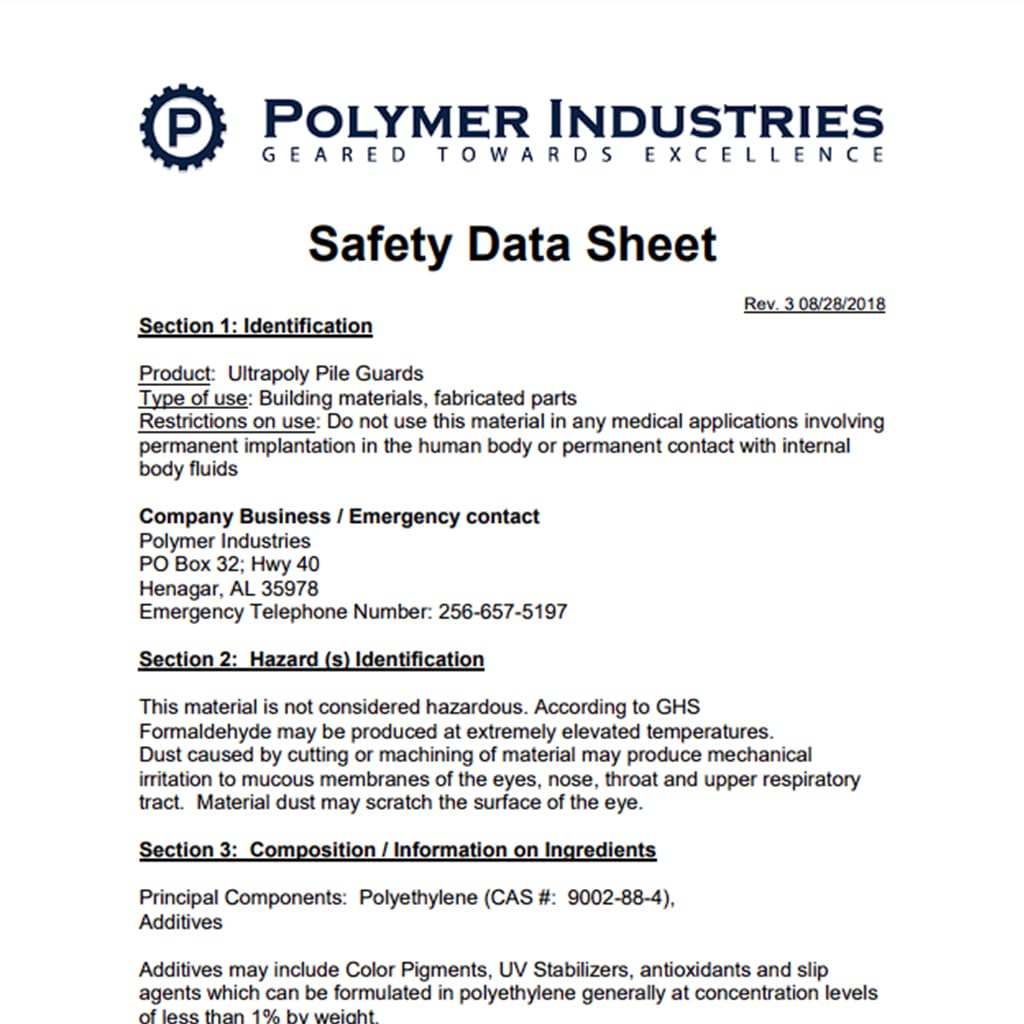

POLYSLICK® PILE GUARDS have excellent impact and abrasion resistance, and a low coefficient of friction, which is proven to be an ideal material in dock applications. The material is ideally suited to harsh marine environments due to its almost zero moisture absorption and chemical resistance to saltwater. The material’s extremely high molecular weight essentially holds the material together during the extreme force transfers between the ship and dock.

Have questions or need samples?

Features

- Impact resistant

- Abrasion resistant

- UV protected

- Will not corrode, rot or splinter

- Resists marine borers and barnacle growth

- Non-sparking

- Can be drilled, chamfered and fabricated to meet customer specifications

Colors

Black

Yellow

Custom colors available

Finishes

Smooth

Applications

- Dock Facings

- Pile Facings

- Boat Rails and Gunnels

- Canal Lock Door Panels

- Lock and Dam Guidewall

- Dry Dock Walls and Side Rails

- Floating Dock

- Pipeline Fenders

- Pier Protection

- Canal Lock Walls

- Keel and Bilge Block Facings

- Wharf, Pier, and Lock Fenders

- Offshore Pump Station Fenders

Sizes

Thickness

1.25 inch / 32 mm

Width x Length

12 x Up to 30 feet / 300 x Up to 9 Meters

Related Industries

Aerospace

Agriculture

Automotive

Building & Construction

Chemical

Food & Beverage