Our Products

Prepare a meal, step onto a new playground, or use a public restroom and chances are you’ll encounter a plastic product made by Polymer Industries. Cutting board sheets, playground equipment, and restroom partitions are only a few of the many applications of Polymer Industries’ wide range of products.

Densetec Materials

Polymer Industries’ Densetec® High Density Polyethelyne sheet exhibits the properties of high impact strength, abrasion resistance, and low coefficient of friction. The material is also moisture, stain and odor resistant, and is FDA approved to be used in the food processing industry. The material’s durability makes it ideally suited for a variety of applications such as water tanks, chute linings and numerous industrial uses.

Polymer Industries’ Densetec® HMW is the extruded material needed when Densetec® HDPE is not enough and Polyslick® UHMW is not necessary. Densetec® HMW has higher impact strength than HDPE and is more abrasion resistant. The fact that Densetec® HMW is more wear resistant than standard HDPE, and is more economical than standard UHMW makes it the ideal material for wear applications and machined parts. It may also be used in applications such as snowplow linings and fertilizer spreaders.

Polymer Industries’ Densetec® LDPE Sheet is a material that’s soft, flexible, and tough, even at low temperatures. Because of the fact that Densetec® LDPE has very good formability traits and is very pliable, it is an ideal material for the orthotics and prosthetics industry. Densetec® LDPE has very good chemical resistance and low moisture absorption which makes it ideal for the chemical industry. Densetec® LDPE also has exceptional environmental stress crack resistance properties.

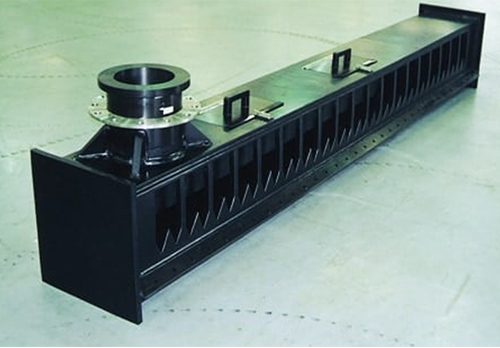

Polymer Industries’ Densetec® HDPE Pipe Grade is a higher molecular weight material than our standard Densetec® HDPE. The material displays improved performance characteristics in a variety of piping applications. In addition, the material is UV stabilized and ideal for use in demanding outdoor applications. It retains its properties between -220°F and 180°F and resists most chemicals. It is also NSF certified under Standard 61 to be used in potable water piping systems. Densetec® HDPE Pipe Grade can be used in a variety of applications including manhole lids and bottoms, pipe reducers, trenches, sumps, pipe flanges, pipe end caps, tanks, milled flange adapters and lifting lugs.

Polymer Industries’ Densetec® Homopolymer Polypropylene exhibits the properties of high corrosion resistance, high temperature resistance, and great tensile strength. It maintains its stiffness at elevated temperatures and displays incredible resistance to organic solvents, degreasing agents, and electrolytic attack. In addition, the material is lightweight, and stain and moisture resistant. Due to its chemical resistance, Densetec® Homopolymer Polypropylene is ideally suited to be used with a wide range of chemicals. Its resistance to aggressive media permits it to be used in laboratories and a large variety of industrial applications. The material resists most strong acids and bases even at relatively high temperatures and oncentrations.

Densetec Specialties

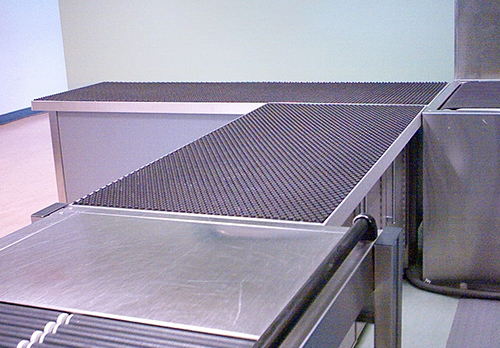

Densetec® Anti Skid is specifically designed for the playground and marine industries incorporating the latest available technologies to produce a non-skid surface ideal for all type of flooring applications. Firstly, Anti Skid incorporates an embossed surface with your choice of either round or square protrusions on one side of the sheet. These protrusions actually grip the tread of the shoe of the person walking on the surface.

Polymer Industries integrates the antimicrobial protection into the product during the manufacturing process. Our antimicrobial material kills or inhibits the growth of microorganisms caused by bacteria, algae and fungi. Our products are also non-porous and kill the spread of bacteria resistant to moisture and mildew.

Traditional wooden cutting boards are no match for boards fabricated with Densetec® Cutting Board from Polymer Industries. Wood and other materials absorb bacteria, splinter, chip, swell, peel, rot, warp, bend and crack. Densetec® Cutting Board eliminates those problems, substantially outlasting cutting boards made from materials other than HDPE.

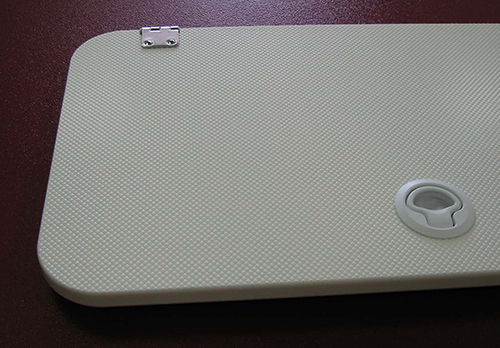

Densetec® Marine Board is specially formulated to withstand the rigors of harsh outdoor marine environments. It is UV-stabilized to resist damage and retain its beauty, even after years of direct sunlight. Increasingly, Densetec® Marine Board is replacing wood and laminates in boating applications. It does not splinter,crack, delaminate, rot, swell, or absorb water like traditional materials. Even under heavy foot traffic on yacht decks, it remains virtually maintenance-free. In addition, there is no need to stain or paint Densetec® Marine Board every few years. The color is integrated with the polymer and retains its vibrant appearance better than painted wood.

Densetec® Partition Board is the ideal partition material for a wide variety of commercial applications such as schools, parks, stadiums, office buildings and airports. The durability of our material makes it immune to such problems as vandalism and constant traffic. In addition, the material is totally unaffected by water and humidity preventing it from shrinking, expanding, bowing, warping or delaminating in any way whatsoever.

Densetec® Playground Board is making a big splash in the playground industry. The variety of bright contrasting colors make it perfectly suited to this environment where high impact colors are required. Because the color is embedded in the sheet, it never needs painting. Especially with the rigors and abuse that children inflict upon playground equipment, this material lasts much longer than wood.

Densetec® Shield is a product specially designed for nuclear shielding applications. The material employs 5% Boron by weight to shield neutrons in a variety of applications including high intensity X-rays, cancer treatment facilities, nuclear submarines, and nuclear power plants.

The material is manufactured by extruding one color on the inside and a contrasting color on the outside. The layers are combined while the material is still molten. The result is a homogeneous sheet that is guaranteed not to delaminate, crack or chip. It is superior to other sign materials, which are separate layers of material laminated together.

Densetec Green

Polymer Industries operates with a clearly defined vision for the future with a priority of caring for our planet. Through our sustainability efforts, manufacturing resources and

Densetec® Post Consumer is a 98% (2% color) post consumer product that can be used in a variety of applications. Densetec® Post Consumer is manufactured using a HDPE resin that has been compounded and processed from products such as detergent bottles and/or milk jugs that have been saved from our nation’s land fills. Densetec® Post Consumer is Polymer Industries contribution to the “Green Movement” and can be produced for a minimum run, per color, per thickness.

Densetec® Post Industrial LW is an HDPE utility grade sheet material that is approximately 20% lighter that standard weight HDPE sheet. The material employs a foamed core capped with full weight skin to achieve weight reduction. The material is ideal as a replacement for plywood in a variety of applications where moisture absorption is a concern.

Polyslick Ultra-High Molecular Weight

POLYSLICK® BUS CURB is a custom formulated synthetic fender designed to reduce street curb and transit station curb damage as well as reduce damage to bus wheels and tires. Damage typically occurs when drivers are executing “precision or close docking”. This safety oriented action is required to reduce the gap between the curb or station platform and the boarding floor of the bus. POLYSLICK® BUS CURB allows buses to impact and glide smoothly along the curb face achieving a minimal and safer boarding gap while protecting the curb and bus.

UHMW fender facings bolted or bonded to a fender front creates an unbreakable, low friction shield which protects surfaces from impact and abrasion. UHMW can be designed into the construction of new fendering structures, enduring continuous impact and rubbing, prolonged ultra violet light exposure, wide temperature variations, salt and chemical contact. UHMW fenders can be made of UHMW, crosslinked UHMW, or reprocessed UHMW.

The unique leaf spring shape of Flexi Fend allows it to flex with impact and return to shape with no permanent damage. Fenders fully recover from repeated collisions and heavy loads. Made of lightweight UHMWPE, Flexi Fend installs easily and is virtually maintenance free.

The docking or berthing of a ship puts an enormous pressure and friction transferred between the ship and the shore fixtures. This can lead to large scale damage and deterioration to the shore fixtures. Traditionally, docks have used rubber and timber systems to provide a barrier between the ship and the dock. However, timber quickly deteriorates in the harsh marine climate while rubber is prone to tearing and catastrophic failure in this application.

Polyslick® Rocket Plate is a 100% virgin UHMW-PE (Ultra High Molecular Weight Polyethylene) sheet product with hemispherical nodules on one side designed to reduce surface contact facilitating easier movement and rotation of heavy material in any direction. Low friction, lightweight, impact resistant, and cost effective are just some of Rocket Plate’s features along with being easy to install and requiring virtually no maintenance.

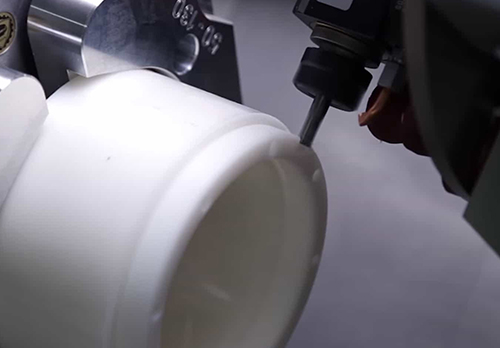

Polyslick® UHMW Rod exhibits all of the durable qualities of our Polyslick® UHMW Sheet making it perfect for the application where sheet stock is not suitable. The material is ideally suited for the manufacture of bushings, bearings, rollers, and augers as there is much less wasted material than if the material was made out of sheet stock. Polyslick® UHMW Rod is available in up to 10 inches in diameter and is available out of stock in natural virgin and black reprocessed grades.

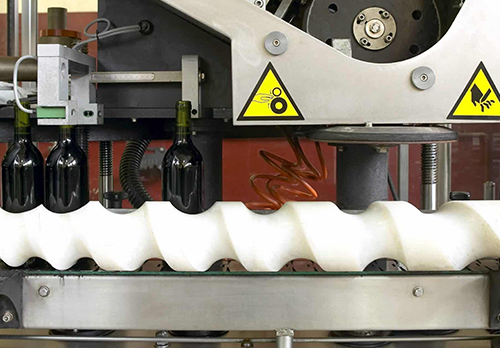

Polyslick® UHMW Sheet exhibits the properties of excellent impact strength, abrasion resistance, low coefficient of friction, as well as very good chemical resistance. This industrial grade material is also moisture, stain and odor resistant, and is FDA approved to be used in the food processing industry. The material is ideally suited for wear applications especially in contact with metals.

Mechetec Engineering Plastics

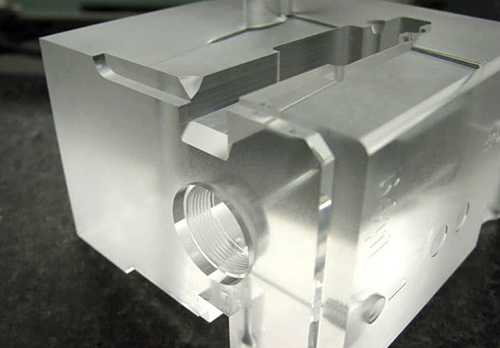

MECHETEC® Acetal (polyoxy-methylene) offers design engineers a superior blend of strength, stiffness, lubricity, and dimensional stability. These properties, along with inherent machining ease, have made MECHETEC® Acetal one of the most widely used engineering grade thermoplastics. To meet specific application configurations and to maximize production efficiency, Polymer Industries offers a broad array of MECHETEC® Acetal stock shapes.

MECHETEC® Delrin® (polyoxy-methylene) offers design engineers a superior blend of strength, stiffness, lubricity, and dimensional stability. These properties, along with inherent machining ease, have made MECHETEC® Delrin® one of the most widely used engineering grade thermoplastics. To meet specific application configurations and to maximize production efficiencies, Polymer Industries offers a broad array of MECHETEC® Delrin® stock shapes.

Since its introduction in 1938, Nylon has become one of the world’s most widely recognized and utilized engineering grade thermoplastics. Nylon’s unique combination of high strength, good toughness, outstanding chemical resistance, and excellent wear and abrasion resistance have made it the material of choice for product designs in a multitude of industries. When used to replace wear grade metals like brass and bronze, no other material provides the combination of extended wear life, light weight, and low fabricated part cost of Nylon.

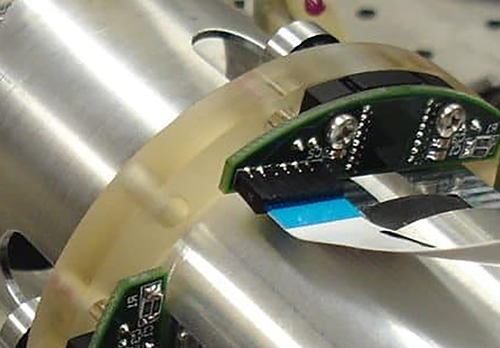

MECHETEC® PPO (blend of polyphenylene oxide and styrene) is an amorphous thermoplastic that offers a superior blend of physical strength, flame resistance, and outstanding electrical properties. Unlike many amorphous materials that tend to steadily lose strength as temperatures increase, MECHETEC® PPO maintains its high stiffness to temperatures in excess of 200°F.

MECHETEC® PC (Polycarbonate) is a transparent thermoplastic that exhibits extraordinary impact resistance and excellent electrical properties. In addition, its low moisture absorption rate and good chemical resistance make it an extremely versatile engineering material and allows for its use in a multitude of industrial applications. Unfilled MECHETEC® PC is a mechanical grade material with light transmittance of approximately 88%. For applications requiring additional stiffness, a 20% glass fiber filled option is available.

Mechetec High Performance

MECHETEC® PET from Polymer Industries is a semi-crystalline polyester terephthalate (PET) polymer that exhibits excellent strength, rigidity, and is easily machined. Additionally, this material offers dimensional stability and wear resistance that meets or exceeds that of nylon or acetal. Due to it’s superior chemical resistance and food contact approvals, MECHETEC® PET stock shapes are the preferred material for components in food processing applications such as pistons, valves, feed screws, and food product forming and extrusion dies.

MECHETEC® PVDF (Polyvinylidene Fluoride) is a non-reinforced highly crystalline fluoropolymer that combines exceptional chemical resistance with superior strength and stability. When compared with traditional fluoropolymers like PTFE, MECHETEC® PVDF offers up to three times the typical strength and stiffness while maintaining unparalleled resistance to even the harshest chemicals—even at temperatures up to 300°F.

MECHETEC® PSU (Polysulfone) is an amorphous high performance thermoplastic material that has proven performance at elevated temperatures. Good mechanical properties along with thermal stability allow for its use in load bearing applications over broad temperature ranges. Other notable attributes include flame retardant, excellent radiation resistance, and good chemical resistance. The ability of MECHETEC® PSU to withstand common sterilization techniques supports its use in numerous sanitary applications such as medical instruments and food processing machinery.

MECHETEC® PEI (Polyetherimide) is an amorphous thermoplastic that is manufactured from SABIC Innovative Plastics’ ULTEM resin. MECHETEC® PEI is extremely rigid, dimensionally stable, and able to withstand continuous operating temperatures of 340˚F. Because it offers superior resistance to autoclave sanitizing and is FDA/USDA compliant, MECHETEC® PEI is routinely specified for reusable machined components used in the medical and pharmaceutical industries.

MECHETEC® PEEK ( Polyetheretherketone) is a semi-crystalline high temperature thermoplastic that offers design engineers a truly unique combination of exceptional performance characteristics. When compared with other engineering polymers, this material ranks as the best or nearly the best in every performance category. MECHETEC® PEEK has a relative thermal index of 480°F and has a UL 94 flammability rating of V-0, with very low levels of smoke generation and toxic gas emission.

Ultrapoly Anti-Skid

Ultra Non-Skid® technology initially developed for the United States Navy has been scaled down for commercial use. New to the Ultra Non-Skid® family is BraxxTM permanent non-skid sheet. These non-skid technologies are a direct replacement for non-skid tapes and paints for industrial applications.

Ultra Non-Skid® technology initially developed for the United States Navy has been scaled down for commercial use. New to the Ultra Non-Skid® family is Luns permanent non-skid sheet. These non-skid technologies are a direct replacement for non-skid tapes and paints for industrial applications.

Avalanche Liners

Our Medium Duty dumptruck liner is manufactured from a high molecular weight (HMW) polyethylene extrusion. This plastic liner is designed for lighter hauling, and is subsequently priced more cost-effectively than our heavier duty dumptruck liners. The Mid-Grade dumptruck liner ranges from 1/4” to 1/2” thickness, and can be manufactured in widths from 1’ to 16’. We recommend against hauling any asphalt with this grade of dumptruck liner.

Our Heavy-Duty liner is manufactured from an ultra-high molecular weight (UHMW) polyethylene extrusion to produce a plastic liner designed for heavy-duty hauling. When compared to HMW liners, UHMW liners are 3-5X more resistant to wear. Heavy-Duty liners are suitable for larger rock and heavier hauling. The Heavy-Duty liner ranges from 1/4” to 3/4” thickness, and can be manufactured in widths from 1’ to 16’ feet wide.

The High Temperature liner is designed to haul hot asphalt up to a temperature of 400 degrees Fahrenheit. Our Heat Stabilized dump truck liner is our most durable & protective liner, while also utilizing additives to provide for our best sliding surface to fight against material build up and additional hydraulic pressure used to extract material from your dump truck bed. When compared to HMW liners, UHMW liners are 3-5X more resistant to wear.

TPS Storm Panels

The TPS ClearGuard® Hurricane Panels are made with super tough Polycarbonate resin (a type of plastic) that will not rust, shatter, or corrode. Our TPS ClearGuard® Hurricane Panels allow natural light to filter in during storm related power outages. With up to 85% natural light transmission, every homeowner should be sure to have a clear panel system that allows light in and visibility out.

The TPS ValueGuard® Hurricane Panels are manufactured using the highest quality proprietary UV resistant polymers available. The TPS ValueGuard® Hurricane Panels offer most of the features of our premium ClearGuard® product, but at substantial savings.